Poly Spiral Wrapped Pulling Twine, Blue/White, 6,500' – Fiber Savvy

These products are all Made to Order Which means they are non-cancelable and non-refundable Minimum Order Quantities May Apply Description Poly Pull Line Spiral Wrapped Pulling Twine This poly pull line spiral wrapped pulling twine in blue/white is available in 6,500 ft lengths and in supplied in plastic pails for easy use and storage. Poly pull line spiral wrapped pulling twine was designed for pulling or blowing through conduit. Features Features Poly Spiral Wrapped Pulling Twine Ideal for Pulling or Blowing Through Conduit Ships in Plastic Pails for Easy Use and Storage Minimum Tensile Strength 210lbs. Available in 6,500ft Lengths Specifications Specifications Poly Pull Line Spiral Wrapped Pulling Twine Size Length (Feet) Minimum Tensile Strength (Lbs) Package Type 650 6,500 210 Pail 220 2,200 500 Pail Please See Our Care and Use Page Additional Information Proper Care and Use

These products are all Made to Order

Which means they are non-cancelable and non-refundable

Minimum Order Quantities May Apply

Description

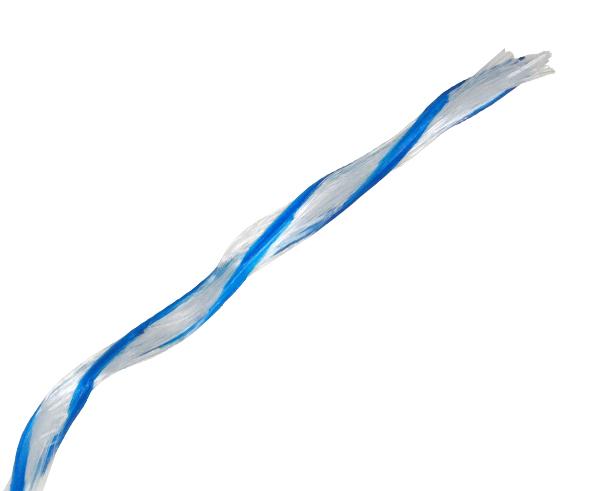

Poly Pull Line Spiral Wrapped Pulling Twine

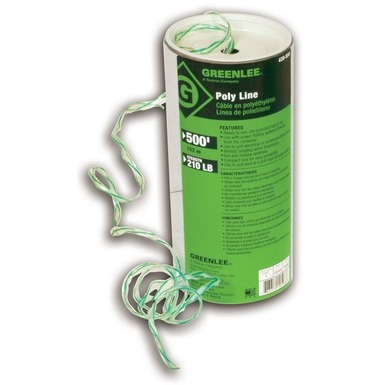

This poly pull line spiral wrapped pulling twine in blue/white is available in 6,500 ft lengths and in supplied in plastic pails for easy use and storage. Poly pull line spiral wrapped pulling twine was designed for pulling or blowing through conduit.

Features

Features

Poly Spiral Wrapped Pulling Twine

Ideal for Pulling or Blowing Through Conduit

Ships in Plastic Pails for Easy Use and Storage

Minimum Tensile Strength 210lbs.

Available in 6,500ft Lengths

Specifications

Specifications

Poly Pull Line Spiral Wrapped Pulling Twine

Size

Length (Feet)

Minimum Tensile Strength (Lbs)

Package Type

650

6,500

210

Pail

220

2,200

500

Pail

Please See Our Care and Use Page

Additional Information

Proper Care and Use

Warning: Misuse of Ropes Could Result in Serious Injury

CAUTION: Use of Working Loads

Because of the wide range of rope use, rope condition and exposure to the various factors affecting the rope, it is impossible to make blanket recommendations as to the correct choice of rope to use. However we have provided the tensile strength for each diameter and type of rope. These strengths are based on tests of new and unused rope, with appropriate splices. Proper choice, care and inspection of the rope are essential for reasonably safe use of the rope. Consult your cordage vendor for proper use.

Dynamic Loading Voids Normal Work Loads

Dynamic Loading occurs when rope is subjected to sudden or extreme stress. Figures given as working loads are void if rope has been subjected to dynamic loading, high temperatures, long periods of load, extreme stress, improper storage.

Effect of Temperature on Tensile Strength

The tensile strength charts apply to ropes tested at normal room temperature (70°F). Ropes have lower tensile strength at higher temperatures. Continued exposure at elevated temperatures causes permanent damage.

Avoid Abrasion

All ropes should be protected against sharp edges and abrasive surfaces. When worn areas are visible, the tensile strength is compromised. Protect the rope's surface with chafing gear around the rope.

Avoid Chemicals

Acids and Alkalis are damaging to ropes and fibers. Caution should be used when ropes are used around building cleaning acids, cast soda and paints. Proper inspection should be made of rope prior to use.

Rope Inspection

Rope Inspection should be a continuous process that takes place before, during and after each use. When fiber shows wear in any given area, the rope should be re-splices, downgraded or replaced.

Knots and Splicing

Splicing should be used instead of knots. Knots can decrease a rope's tensile strength by up to 50%

Rope Storage

All ropes should be stored in a clean dry location, out of direct sunlight and extreme heat. Natural fiber ropes, if not kept dry, will rot over time, reducing tensile strengths dramatically.

Sunlight Degradation

Polypropylene and polyethylene ropes are subject to ultraviolet degradation. The product should be replaced when signs of excessive deterioration is indicated by discoloration or broken filaments. Tensile strengths may be dramatically reduced by sunlight degradation.

Dielectric Properties

Dielectric property testing applies only to new, unused clean rope and holds true only under these ideal conditions. Dirt, grease, entrapped moisture, or other contaminants will increase conductivity greatly. Nylon or natural fiber ropes would not be used around energized lines. Rope dielectric properties must be tested under actual operation conditions.

What's In The Box

What's In The Box

Qty 1 bucket of - Poly Pull Line Spiral Wrapped Pulling Twine, Blue/White, 6,500'

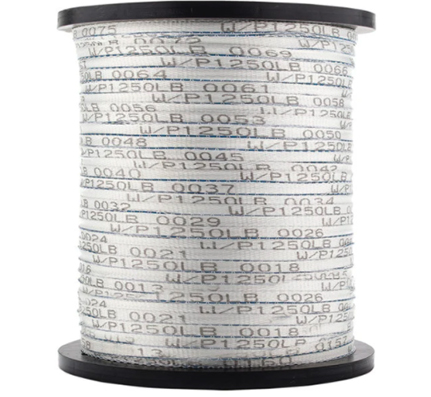

Ideal 31-1250-10 - Pro-Pull Measuring Pull Tape, 1250lb, 1000ft Reel

Poly-Pull Twine - Seaco Industries

Millennium - Pull Tape & Rope - HDPE Smoothwall Conduit & Pipe

All Products - Erin Rope Corporation

IDEAL 6500-ft Nylon Pull Line in the Fish Tape & Poles department at

6500' JET LINE 210LB BREAKING STRENGTH GRAYBAR POLY LINE Surplus Traders

This poly pull line spiral wrapped pulling twine in blue/white is available in 6,500 ft lengths and in supplied in plastic pails for easy use and

Poly Pull Line Spiral Wrapped Pulling Twine, Blue/White, 6,500' In A Bucket

Spiral Wrap Twine

FRANK WINNE AND SON, INC 71973

Everbilt 3/32 in. x 6500 ft. Polypropylene Twisted Utility Tying Twine, White 72986 - The Home Depot

Cable Installation Tools – Tagged cable-pulling-rope – Fiber Savvy

All Products - Erin Rope Corporation

Xpose Safety Parcel Twine - Polyester Cord Twine String 225' - Extra Strong Thick White String Spool - Ties Easily and Securely- Packaging Rope, Lacing Cord